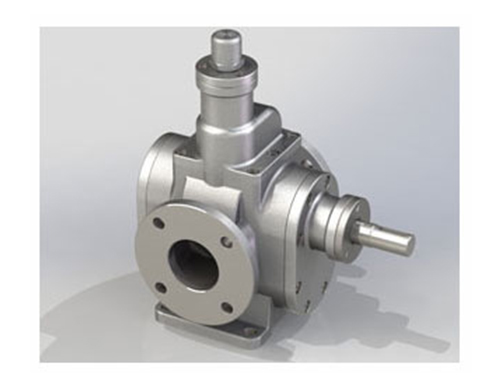

齿轮泵油的换油 Reciprocating pump oil in oil

为了取得 佳效果, 将润滑部位 清洗干净。清洗步骤包括放掉旧油,除掉沉积物。 In order to achieve the best effect, must will lubrication part clean thoroughly. Cleaning steps including let off the old oil, remove sediment.

一、 曲轴箱 A, crankcase

1、将齿轮泵停下,温度仍然接近运行温度时,按通常方式将油品放掉。 1, will pump stop, the temperature is still close to the operating temperature, the usual way will oil let off.

2、放掉过滤机中的油并清洗干净,或另换过滤机。 2, let off filter of oil and clean, or the other in filter.

3、清理冲洗过滤机或另换过滤机。 3, clear flush filter or other change filter.

4、将合适粘度级别的新油加入齿轮泵曲轴箱。由于清洗过程中松下来的颗粒物和沉积物可能会降低过滤机的寿命,因此建议在运行期间定期监测过滤机。 4, will be suitable viscosity level of new oil to join pump crankcase. Due to the cleaning process of particle and sediment matsushita to may reduce the service life of filter, so suggest during operation regularly monitor filter.

5、重新启动齿轮泵时,请遵照制造商的推荐。 5, restart the gear pump, please follow the manufacturer's recommended.

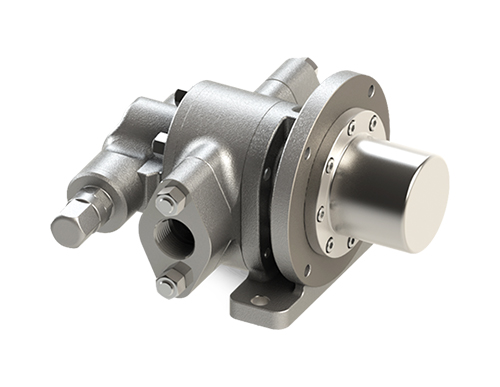

二、汽缸 Second, the cylinder

1、一旦可能,遵照制造商的推荐拆下阀和出口阀。 阀门、可及的空气通道、内部冷凝器及分离器上 的积碳和沉积物。但是管道中仍然有可能存在沉积物和积碳,这些会沉积物和积碳会逐步溶解。因此,新 油运行初期 对齿轮泵沿线进行经常性的检查。 1, as soon as possible, in accordance with manufacturer's recommended remove the inlet valve and outlet valve. Remove valve, and air channel, internal condenser and separator on the carbon deposition and sediment. But there are still in the pipe may exist sediments and carbon deposition, these will be sediments and carbon deposition will gradually dissolve. Therefore, the new oil early operation must be along the gear pump for regular inspection.

2、清理后,按照齿轮泵制造商的要求启动齿轮泵。 如果有 先跑合,采用齿轮泵普通操作所需要的同粘度的油品。跑合150-250小时后,放掉跑合油。

2, cleaning, according to the requirements of the gear pump manufacturers start pump. If it is necessary to running, the gear pump common operation need with the viscosity of oil. Running 150-250 hours, let off running oil.

"客户至上”是我们的经营宗旨,全心全意的做好服务是“客户至上”的必然要求。

泊东油泵产品国标标准品质保证

公司严格按着合同约定安排生产、发运,保证按着合同约定时间供货。

泊东油泵产品质量保险

泊东油泵的每一台产品均经“中国人民保险公司”进行产品质量责任保险。