齿轮泵压力变小的几个原因 Pump pressure decrescen

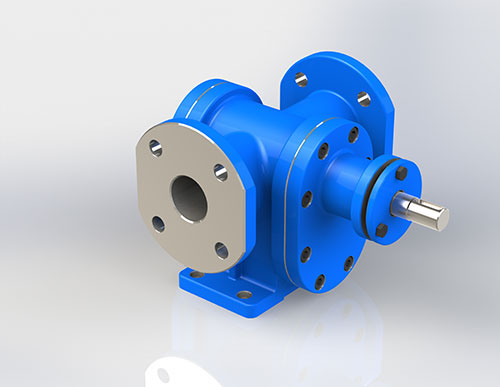

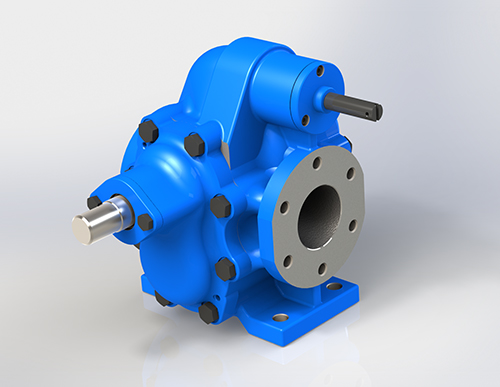

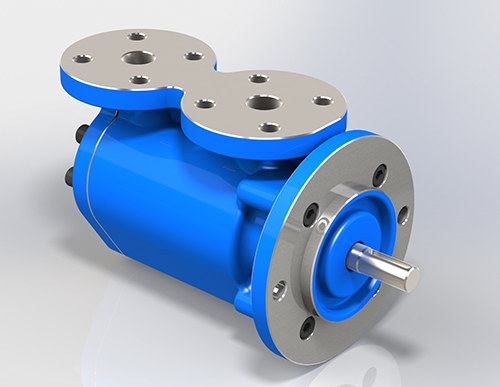

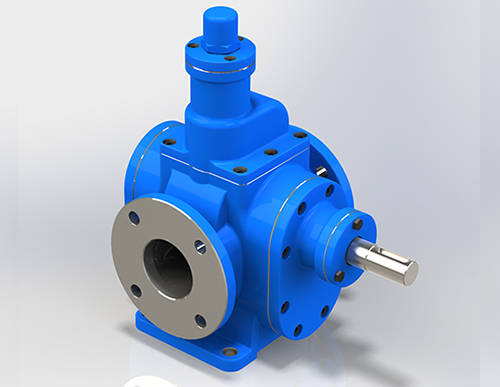

齿轮泵一般用的时候,用的时间不长压力就会减小,齿轮泵的压力主要来自齿轮与壳体间的密闭容腔,但齿轮要旋转必然存在端面间隙和径向间隙,要提高齿轮泵输出压力,就需要减小间隙,然而间隙越小,在运行时齿轮高速旋转,摩擦会增大,经过一段时间间隙会变大,压力依然无法升高。一般采用轴向、径向间隙补偿措施。Pump general use, use time is not long pressure will be reduced, pump pressure mainly from gear and shell between airtight capacity cavity, but gear to rotate there must be end clearance and radial clearance, to improve the pump output pressure, they need to reduce clearance, however clearance, the smaller the runtime gear high-speed rotation, will increase the friction, after a period of time gap get bigger, the pressure is still unable to rise. General use of the axial and radial clearance compensation measures.

另外齿轮泵压力提高,齿轮承受的径向力增大,轴承的承载能力会受到考验。有 阀的齿轮泵还要考虑是否 阀不严或超载造成的 阀已经打开,这些都是造成齿轮泵压力变小的原因In addition pump pressure increase, gear bear radial force increases, the bearing capacity will be tested. A relief valve gear pump consider to whether be relief valve is lax or overload caused by the relief valve already open, these are the cause of gear pump pressure caused by smaller.

"客户至上”是我们的经营宗旨,全心全意的做好服务是“客户至上”的必然要求。

泊东油泵产品国标标准品质保证

公司严格按着合同约定安排生产、发运,保证按着合同约定时间供货。

泊东油泵产品质量保险

泊东油泵的每一台产品均经“中国人民保险公司”进行产品质量责任保险。