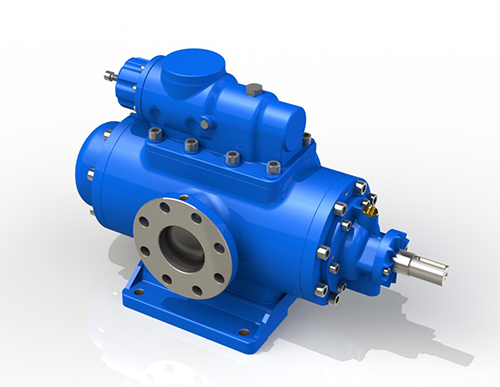

怎样修理齿轮泵How to repair gear pump

随着使用齿轮泵时间的增长,齿轮泵会出现泵油不足,甚至不泵油等故障,主要原因是有关部位磨损过大。齿轮泵的磨损部位主要有主动轴与衬套、被动齿轮中心孔与轴销、泵壳内腔与齿轮、齿轮端面与泵盖等。润滑油泵磨损后其主要技术指标达不到要求时,应将其拆卸分解,查清磨损部位及程度,采取相应办法予以。

With the growth of the use time, pump will appear pump oil shortage, don't even pump oil fault, the main reason is the related parts excessive wear. Pump wear parts are mainly drive shaft and bushing, passive gear center hole and shaft pin, pump shell lumen and gear, gear face and pump cover, etc. Lubricating oil pump wear after the main technical indexes can not reach requirement, should its dismantling, gleaning wear parts and degree, take corresponding measures to repair.

一、主动轴与衬套磨损后的A, drive shaft and bushing wear after the repair

齿轮泵主动轴与衬套磨损后,其配合间隙增大,必将影响泵油量。遇此,可采用修主动轴或衬套的方法恢复其正常的配合间隙。若主动轴磨损轻微,只需压出旧衬套后换上标准尺寸的衬套,配合间隙便可恢复到允许范围。若主动轴与衬套磨损严重且配合间隙严重超标时,不仅要 换衬套,而且主动轴也应用镀铬或振动堆焊法将其直径加大,然后再磨削到标准尺寸,恢复与衬套的配合要求。Pump drive shaft and bushing wear, the tolerance clearance increases, will affect oil pump. In this, can use repair drive shaft and bushing method to recover its normal fit clearance. If the drive shaft wear mild, just press the old bush changed after standard size bushing, fit clearance can be restored to allow range. If the drive shaft and bushing wear serious and fit clearance exceeds bid badly, not only to replace liner, and drive shaft is also used chrome plated or vibration overlaying welding method will increase its diameter, and then grinding to the standard size, restoration and bushing with the requirements.

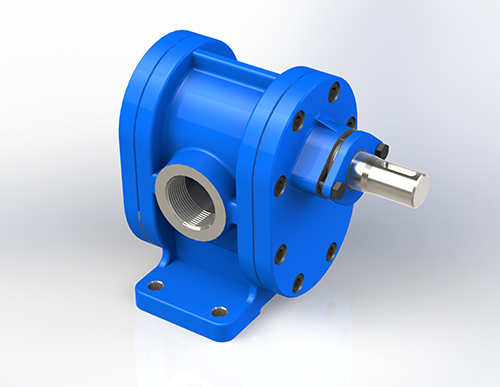

二、润滑油泵壳体的修理Second, the lubricating oil pump housing repair

壳体裂纹的修理:壳体裂纹可用铸508镍铜焊条焊补。焊缝须紧密而元气孔,与泵盖结合面平面度误差不大于0.05毫米。主动轴衬套孔与从动轴孔磨损的修理:主动轴衬套孔磨损后,可用铰削方法磨损痕迹,然后配用加大至相应尺寸的衬套。从动轴孔磨损也以铰削法磨损痕迹,然后按铰削后孔的实际尺寸配制从动轴泵壳内腔的修理:泵壳内腔磨损后,一般采取内腔镶套法,即将内腔搪大后镶配铸铁或钢衬套。镶套后,将内腔搪到要求的尺寸,并把伸出端面的衬套磨去,使其与泵壳结合面平齐。

Shell crack repair: shell crack available casting 508 nickel copper electrode tinker. Weld shall be closely and yuan hole, and pump cover joint surface flatness error is not more than 0.05 mm. Active shaft bushing hole and driven shaft hole wear repair: active shaft bushing hole after wear, usable ream method eliminate wear trace, and then with increasing to corresponding size bushing. Driven axle hole wear also to ream method eliminate wear trace, and then press after ream holes in the actual size configuration driven shaft

阀座的修理:限压阀有球形阀和柱塞式阀两种。球形阀座磨损后,可将一钢球放在阀座上,然后用金属棒轻轻敲击钢球,直到球阀与阀座密合为止。如阀座磨损严重,可先铰削除去磨痕,再用上法使之密合。柱塞式阀座磨损后,可放入少许气门砂进行研磨,直到密合为止。Pump shell lumen repair: pump shell lumen wear, commonly take lumen panel set of method to repair, the inner chamber boring with big with cast iron or steel sleeve. Panel set, will be lumen boring to the size of the requirements, and the end of the bush grinding out to, and the pump shell joint surface level. Seat repair: pressure limiting valve have spherical valve and plunger valve two. Ball valve seat wear, a ball on the seat, then use metal bar gently knock on ball, until the ball valve and valve seat closed so far. Such as seat wear serious, can be ream remove grinding crack, and then use method to closed. Plunger valve seat wear, can put a few valve sand ground, until closed so far.

三、泵盖的修理Three, pump cover repair

工作平面的修理:若泵盖工作平面磨损较小,可用手工研磨法磨损痕迹,即在平台或厚玻璃板上放少许气门砂,然后将泵盖放在上面进行研磨,直到磨损痕迹,工作表面平整为止。当泵盖工作平面磨损超过0.1毫米时,应采取先车削后研磨的办法。

主动轴衬套孔的修理:泵盖上的主动轴衬套孔磨损的修理与壳体主动轴衬套孔磨损的修理方法相同。Work surface repair: if the pump cover work surface wear is lesser, usable hand grinding method eliminate wear trace, namely in the platform or plate glass is put on a few valve sand, and then will pump cover on ground, until wear trace eliminate, the work surface leveling so far. When the pump cover work plane wear depth more than 0.1 mm, should take the first turning after grinding way to repair.

四、齿轮的翻转使用

齿轮泵齿轮磨损主要是在齿厚部位,而齿轮端面和齿顶的磨损都相对较轻。齿轮在齿厚部位都是单侧磨损,所以可将齿轮翻转180度使用。当齿轮端面磨损时,可将端面磨平,同时研磨润滑油泵壳体结合面,以齿轮泵齿轮端面与泵盖的间隙在标准范围内。

Active shaft bushing hole repair: pump cover active shaft bushing hole wear repair and shell active shaft bushing hole wear repair method is the same.Four, the gear turnover use

Pump gear wear mainly in tooth thickness place, and gear face and addendum wear is relatively light. Gear in the tooth thickness parts are unilateral wear, so can turn 180 degrees to use gear. When the gear end wear, but will face grinding flat, and at the same time, grinding lubricating oil pump shell joint surface, to ensure the gear face and pump cover the gap in the standard range.

"客户至上”是我们的经营宗旨,全心全意的做好服务是“客户至上”的必然要求。

泊东油泵产品国标标准品质保证

公司严格按着合同约定安排生产、发运,保证按着合同约定时间供货。

泊东油泵产品质量保险

泊东油泵的每一台产品均经“中国人民保险公司”进行产品质量责任保险。