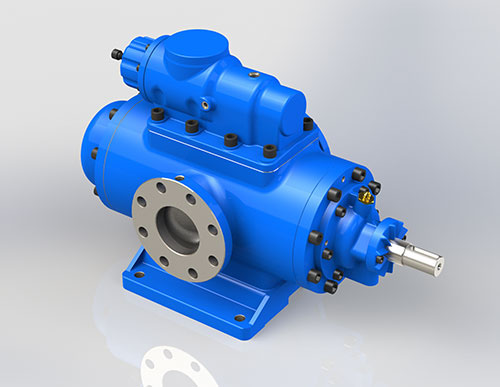

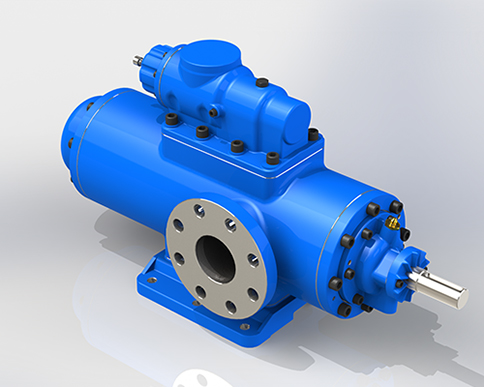

沥青循环泵用型号NYP320-RU-T2-W11高粘度泵 配CZR10

沥青是由不同分子量的碳氢化合物及其非金属衍生物组成的黑褐色复杂混合物,呈液态,是一种和的胶凝材料。用于涂料、塑料、橡胶等工业以及铺筑路面等。

Asphalt is composed of different molecular weight hydrocarbons and non-metallic derivatives of dark brown complex mixture, a liquid, is a kind of waterproof and moistureproof and anticorrosive organic cementing materials.Used in coatings, plastic, rubber and other industrial and paved road, etc.

中文名 沥青Chinese name asphalt

CAS登录号8052-42-4The CAS login number 8052-42-4

EINECS登录号232-490-9EINECS registration number 232-490-9

熔 点 485Melting point 485

沸 点 <470℃Boiling point < 470 ℃

水溶性不溶于水Water soluble does not dissolve in water

密 度 1.15-1.25Dense degree of 1.15 to 1.25

外 观半固体或液体状态Outside view half solid or liquid state

闪 点204.4Flash point 204.4

危险性描述健康危害:中等毒性Describe health hazard risk: medium toxicity

来源煤和石油To the source of coal and oil

成 分沥青质和树脂Into asphaltene and resin

含 量99.48%Containing 99.48%

爆炸下限 30(g/立方厘米)The lower explosive limit (30 g/cm3)

导电性能绝缘体(常温下)Conductivity insulator (room temperature)

沥青属于憎水性材料,它不透水,也几乎不溶于水、丙酮、乙醚、稀乙醇,溶于二硫化碳、四氯化碳、氢氧化钠。沥青及其烟气对皮肤粘膜具有刺激性,有光毒作用和致癌作用。我国三种主要沥青的毒性:煤焦沥青>页岩沥青>石油沥青,前二者有致癌性。沥青的主要皮肤损害有:光毒性皮炎,皮损限于面、颈部等暴露部分;黑变病,皮损常对称分布于暴露部位,呈片状,呈褐-深褐-褐黑色;职业性;疣状赘生物及事故引起的热。此外,尚有头昏、头胀,、胸闷、乏力、恶心、食欲不振等全身症状和眼、鼻、咽部的刺激症状。Asphalt is hydrophobic material, it impermeable, almost insoluble in water, dilute ethanol, acetone, ether, soluble in carbon disulfide, carbon tetrachloride, sodium hydroxide.Asphalt and flue gas of skin mucous membrane irritation, has the light effect and the effect that cause cancer.China's three major asphalt toxicity: coal tar > > oil shale asphalt asphalt, before both have carcinogenicity.The main skin lesions are: asphalt light contact dermatitis, skin confined to the face, neck and other exposed parts;Melanosis, skin lesions often symmetrical distributed in the exposed parts, plate shaped, brown - deep brown - brown-black;Occupational acne;Verrucous vegetations and the accident cause thermal burns.In addition, there are dizziness, head bilges, headache, chest tightness, fatigue, nausea, loss of appetite and other systemic symptom and eye, nose, pharynx and irritation.

煤焦沥青Coal tar

煤焦沥青是炼焦的副产品,即焦油蒸馏后残留在蒸馏釜内的黑色物质。它与精制焦油只是物理性质有分别,没有明显的界限,一般的划分方法是规定软化点在26.7℃(立方块法)以下的为焦油,26.7℃以上的为沥青。煤焦沥青中主要含有难挥发的蒽、菲、芘等。这些物质具有毒性,由于这些成分的含量不同,煤焦沥青的性质也因而不同。温度的变化对煤焦沥青的影响很大,冬季容易脆裂,夏季容易软化。加热时有气味;加热到260℃在5小时以后,其所含的蒽、菲、芘等成分就会挥发出来。Coal tar is a by-product of coking, namely tar distillation residue in distillation kettle black material.It has respectively with refined tar is only physical properties, there is no clear boundaries, is the way of dividing rules softening point in commonly 26.7 ℃ (cube method) for tar, under 26.7 ℃ above for asphalt.Coal tar mainly contains difficult volatilization of anthracene, phenanthrene, pyrene, etc.These substances have toxic, because the content of these compounds is different, the properties of coal tar are so different.The change of temperature has much effect on the coal tar, winter easy embrittlement, summer is easy to soften.Heating from time to tome special smell;Heated to 260 ℃ after 5 hours, its composition such as anthracene, phenanthrene, pyrene will evaporate.

石油沥青asphalt

石油沥青是原油蒸馏后的残渣。根据提炼程度的不同,在常温下成液体、半固体或固体。石油沥青色黑而有光泽,具有较高的感温性。由于它在生产过程中曾经蒸馏至400℃以上,因而所含挥发成分甚少,但仍可能有高分子的碳氢化合物未经挥发出来,这些物质或多或少对人体健康是的。Petroleum asphalt is after crude distillation residue.Depending on the degree of refining, into a liquid, semi-solid or solid at room temperature.Petroleum pitch dark and luster, has higher heat resistance.Because it had distillation in the production process to more than 400 ℃, thus contained little volatile component, but may still have high polymer without volatile hydrocarbons, which more or less is harmful to human health.

沥青Natural asphalt

沥青储藏在地下,有的形成矿层或在地壳表面堆积。这种沥青大都经过 蒸发、氧化,一般已不含有任何毒素。Natural asphalt storage in underground, some forming seam or piled up in the earth's crust surface.The asphalt mostly through the natural evaporation and oxidation, generally do not contain any poison.

沥青材料分为地沥青和焦油沥青两大类。地沥青又分为 沥青和石油沥青, 沥青是石油渗出地表经长期暴露和蒸发后的残留物;石油沥青是将精制加工石油所残余的渣油,经适当的工艺处理后的产品。焦油沥青是煤、木材等物干馏加工所得的焦油经再加工后的产品。工程中采用的沥青绝大多数是石油沥青,石油沥青是复杂的碳氢化合物与其非金属衍生物组成的混合物。通常沥青闪点在240℃~330℃之间,燃点比闪点约高3℃~6℃度,因此施工温度应控制在闪点以下。Asphalt material divided into two categories, pitch and bitumen.Asphalt is divided into natural asphalt and petroleum asphalt, natural bitumen is oil seepage surface after long exposure and evaporation residue;Petroleum asphalt is a residual of residual oil will be refined processing, after appropriate processing products.Bitumen is coal, wood and other organic matter carbonization processing tar after reprocessing of products.Engineering used in the asphalt is the vast majority of asphalt, asphalt is a complex mixture of hydrocarbons with nonmetal derivatives.Usually asphalt flash point between 240 ℃ ~ 330 ℃, flash point is higher than flash point about 3 ℃ ~ 6 ℃ degrees, so the construction temperature should be controlled below the flash point.v

●高粘度泵如何选型How to choice

选择高粘度泵时应该注意泵所输送的具体粘度、工作温度、介质比重、介质成分等等,只有 好的了解高粘度泵所输送的介质情况才能 好的选择所需要的高粘度泵产品。

Should be paid attention to when selecting high viscosity pump pump delivery by the specific viscosity, working temperature, the proportion of medium, medium composition etc., only a better understanding of the high viscosity pump transmission medium condition can better choose the required high viscosity pump product.

了解高粘度泵所输送的介质粘度。因为介质粘度的高低直接影响到选择高粘度泵的转速。must understand the high viscosity pump transmission medium viscosity. Because the medium viscosity directly affects the choice of high viscosity pump speed.

了解高粘度泵所输送介质的性质,例如有没有腐蚀性。understand the nature of the high viscosity pump conveying medium, such as corrosive.

高粘度泵所输送的介质浓度多少、比重多少。 high viscosity pump how far the conveying medium concentration, specific gravity.

Fourth,

高粘度泵所输送的介质。high viscosity pump transmission medium.

高粘度泵输送的介质常温下是否结晶或凝固。the high viscosity pump whether the medium temperature of crystallization or coagulation.

高粘度泵所输送的介质是否有悬浮物。the transmission medium for high viscosity pump suspension.

高粘度泵所输送介质受温度变化情况。high viscosity pump conveying medium affected by temperature changes.

高粘度泵所输送介质的润滑性、清洁度、腐蚀性等。high viscosity pump medium by lubricity, cleanliness, corrosion resistance, etc.

高粘度泵要求压力及出口压力和安装高度。 high viscosity pump inlet pressure and outlet pressure and the installation height.

高粘度泵使用场合的要求。high viscosity pump occasions of explosion-proof requirements.

●高粘度泵的安装调试步骤High viscosity pump installation and debugging steps

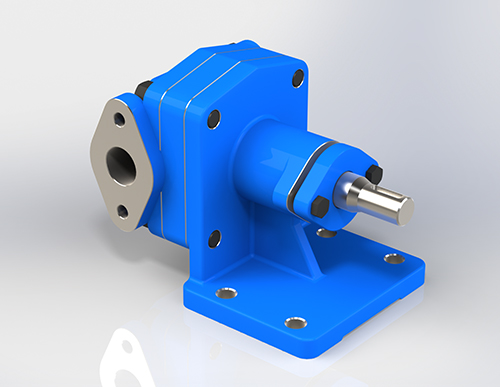

高粘度泵是输送高粘度液体的齿轮泵,应做到在较低的功耗、较少的泄漏、较大的压力下输出 多的流量。在确定所要输送的介质时,应该严格遵循产品说明书上的规定,尽量使用厂家推荐的流体介质,并注意考虑系统的工作温度范围。当希望在某一较宽的温度范围内使用时,输送介质的粘度指数应该高些。输送介质不仅是能量传递的中介,而且也是润滑、密封及传热介质。液体粘度过高会增加内摩擦阻力,降低输出功率,浪费能量,并产生过高的系统温度.高粘度齿轮泵的出口管路上应当设置 阀等保护装置,这样一旦泵的出口通道发生堵塞,就可以打开 阀卸压。对于需要正反转的高粘度齿轮泵,其进出口管路上均需设置 阀。High viscosity pump is conveying liquid with high viscosity gear pump, should be in lower power consumption, less leakage, under the pressure of large output the most traffic. When determining to conveying medium, we should strictly follow the provisions of the product manuals on use manufacturers recommend fluid as far as possible, and pay attention to consider the system operating temperature range. When you want to use in a wide temperature range, medium viscosity index should be higher. Medium is not only the energy transfer intermediary, but also lubrication, sealing and heat transfer medium. Liquid viscosity is too high will increase internal friction resistance, lower output power, waste of energy, and generate high temperature system. High viscosity gear pump outlet pipe shall set up relief valve or other protective device on the road, so once the clogging pump export channels, can open the relief valve pressure relief. For high viscosity gear pump need positive &negative, import and export all needs to set up the line safety valve.

●输送介质的优势:The advantage of the medium:

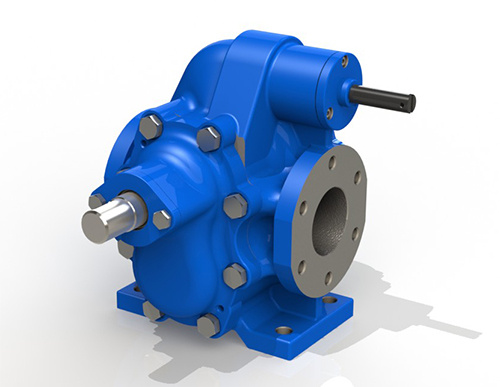

高粘度泵可以输送高粘度、无固体颗粒或细小软颗粒的润滑性介质;,性能稳定,使用寿命长。高粘度泵可以采用保温夹套结构,输送比较高的粘度物料时可以对高粘度泵进行保温,从而降低介质粘度,达到 好的输送效果,而单螺杆泵没有保温夹套结构;高粘度泵在使用一段时间后,如果泵内部间隙磨损后,不用拆泵可以自行根据高粘度泵所输送的物料粘度来调整泵的间隙,调整后和新泵一样可以达到良好的使用效果。高粘度泵可配 阀,当泵或管路系统超压时, 阀门打开,形成内部回流,系统 。而单螺杆泵在泵本身不能设置 阀,只能在管路中设置,提高了设备投入成本和安装成本。选择高粘度泵时 考虑高粘度泵所输送的介质粘度,从而才能来确定高粘度泵的转速范围,根据高粘度泵的转速范围及所需工况条件下高粘度泵的正常流量范围,才能确定高粘度泵具体型号。需要注意的是一般介质可以这样来选择。High viscosity pump can transport high viscosity, high concentration without solid particles or small soft particles lubricity medium; High efficiency, stable performance and long service life. High viscosity pump can be used in a heat preservation jacket structure, transmission is higher when the viscosity of the material can be for thermal insulation in high viscosity pump, thereby reducing medium viscosity, achieve better transmission effect, and the single screw pump heat preservation jacket structure; High viscosity pump in use after a period of time, if the pump internal clearance after wear, don't have to dismantle the pump to according to the viscosity of material delivery by high viscosity pump to adjust the clearance between the pump and adjusted, and the use of the new pump can achieve good effect. High viscosity pump can match the relief valve, when the pump and piping system overpressure, safety valve is opened, the formation of internal reflux, ensure the safety of the system. And single screw pump in the pump itself cannot set the relief valve, can only be set up in line, increase the investment of equipment cost and installation cost. Choosing high viscosity pump must consider the conveying medium viscosity, high viscosity pump order to determine the scope of the high viscosity of the pump rotation speed, according to the working condition of high viscosity of the pump speed range and required high viscosity pump under the condition of normal flow range, to determine the high viscosity pump concrete models. It's important to note that it can be to choose a normal medium.

其中,有些化学介质在 温度下会改变其化学成分,所以需要在选择高粘度泵要特别注意泵的转速是否适合,因为泵的转速越高,正常工作中产生的热量就越大,一旦超过介质所限制的温度,那么就多所输送的介质造成了破坏。还有些食品类介质,比如果酱类,像我们日常中所食用的果酱、花生酱、豆瓣酱等,这些介质要求在输送过程中 不能够破坏其内部的成分进行破坏,这就要求我们所选的泵的转速 要低,才能高粘度泵在输送过程中不破坏所输送的介质。高粘度泵在运转过程中常常会出现卡死、抱轴转不动的现象,主要原因是高粘度泵往往都是输送的高粘度的介质,有些是有一些杂质的混合物理。如果泵的入口没有安装合适的过滤器,那么一旦大一些的硬质颗粒进入泵腔就会把高粘度泵的内外转子卡死,使泵转不动,严重的会把高粘度泵的内外转子毁掉。Among them, some special chemical medium under a certain temperature to change its chemical composition, so need to high viscosity pump in the choice whether to pay special attention to the speed of the pump is suitable for, because the higher the pump rotation speed, the greater the heat generated by the normal work, once more than media limited by temperature, then it is more than conveying medium caused damage. Also some food medium, such as the jam class, as in our daily consumption of jam, peanut butter, broad bean paste and so on, these medium requirements must be in the process of conveying can't destroy its internal composition, this requires that we selected the speed of the pump must be low, to ensure high viscosity pump does not destroy the transmission medium in the process of delivery. High viscosity pump in the operation process often appear stuck, holding shaft fixed phenomenon, the main reason is that high viscosity pump are often transport high viscosity medium, some are some impurities mixed in physics. If the entrance of the pump is not installed the appropriate filters, so once the larger hard particle enters the pump chamber would bring high viscosity pump rotor stuck inside and outside, make the pump turns motionless, serious will destroy high viscosity pump inside and outside of the rotor.

所以建议大家在安装高粘度泵的时候应该选择合适的过滤器来安装在泵的入口。高粘度泵抱轴的现象主要体现在不锈钢高粘度泵的较多,因为不锈钢材质含碳量低,所以热膨胀系数大,一旦泵的温度过高,就会造成泵的内部配件与配件之间的间隙缩小,到 程度以后就会产生抱死现象。所以选择不锈钢材质的高粘度泵是 要注明具体的使用温度,及介质的润滑性。介质粘度的高低与高粘度泵的转速有着密不可分的关系。如果高粘度泵输送的介质粘度过高,而所配的转速也过高的话,就会造成泵的流量很低、泵的噪音很大。如果电机功率还是按常规来配的话,那么电机也会造成过载。主要是泵的转速太高、介质粘度又太高这样就会造成泵阻力很大,电机的瞬间启动电流超过额定电流,造成电机过载;由于转速过高,使高粘度泵在运转时内部转子几乎只是形成了空转,围绕所输送介质打滑,造成吸不上料,或者是流量很小。在这种状况下, 降低泵的转速,加大电机的功率,加大进出口的管径来减少介质的流动阻力。从而来完成介质的输送工作。转速降低以后,泵的流量会反而增加,而且泵的噪音会降低,但肯定打不到理论流量。所以如果与实际工况需要流量相差太多的话,那就只能 好型号 大一点的泵。So suggest you at the time of installation of high viscosity pump should choose the appropriate filter to installed in the entrance of the pump. The phenomenon of high viscosity pump holding shaft mainly reflects in the stainless steel of high viscosity pump is more, because of low carbon stainless steel material, so the thermal expansion coefficient is big, once the temperature of the pump is too high, can cause the interior of the pump parts and accessories the clearance between the narrow, to a certain degree after tends to lock phenomenon. So choose stainless steel high viscosity pump is must indicate the specific temperature, and medium lubricity. The discretion of the medium viscosity and high viscosity pump rotating speed of the intimate relationship. If the high viscosity pump medium viscosity is too high, and with the rotation speed is too high, will cause the pump flow rate is very low, the noise of the pump is very large. If motor power or conventional match, then the motor can cause overload. Mainly is the pump speed is too high, medium and high viscosity resistance is very big, this will cause pump motor moment of starting current more than rated current, motor overload; Due to high speed, high viscosity pump inside the rotor is barely formed when running idle, surrounding medium by sliding, cause not feeding, or flow rate is small. Under this situation, we must reduce the speed of pump, increase the power of the motor, increase the import and export of pipe diameter to reduce the flow resistance of the medium. Thus to complete medium transport work. Speed is reduced, the pump flow rate will increase instead, and the noise of the pump will be lower, but certainly can't flow theory. So if you need to flow with the actual working condition differ too much, it can only be better model bigger pump.

高粘度泵容易出现的另一个问题就是从动齿轮的销轴容易磨损,特别是对于输送没有润滑性的介质时,销轴磨损特别快。对此我公司改进加工工艺在原有的基础之上通过设计改进给销轴配套加了一套注油润滑系统。在高粘度泵正常运转的情况下通过内转子的旋转产生的离心力形成的负压,利用注油系统通过通道给销轴注油,从而解决了高粘度泵销轴磨损快的这一泵行业中存在的难题。Another problem of the high viscosity pump is driven gear pin easy to wear and tear, especially for conveying without lubrication medium, pin shaft wear particularly fast. I improved processing technology on the basis of the original company through special design improvements to pin shaft supporting a grease lubrication system. Under the condition of the high viscosity of the normal operation of pump centrifugal force produced by the rotation of the rotor within the formation of the negative pressure, the use of injection system through the special channel to pin shaft oil, so as to solve the high viscosity pump pin shaft quick wear of the problems that exist in the pump industry.

●高粘度泵起动前要检查下列内容:

1.检查泵、齿轮箱和电机的对中程度;

2.检查过滤器中有没有焊皮和金属渣;

3.检查各连接部位连接是否紧固;

4.检查管路压在泵上的力和力矩是否超过给定的数值,如果温度较高,还应检查管路是否有膨胀节;

5.检查电气连接的正确性及电机的额定值,并检查电机转动方向是否正确;

6.检查泵的转动方向是否正确;

7.如有 阀, 阀安装 正确;

8.检查泵轴是否转动灵活;

9.泵的内部不能是干的,特别是需要自吸的时候,应向泵内灌注一些油或输送的液体;

10.泵组装时在零件的表面有防护液,如果这种液体不能和泵送液体相容,则 清洗;

11. 好在管路上安装压力表和真空表,方便观察泵的工作状态;

12.检查机械密封箱是否注满液体;

13.检查管路的阀门是否打开;

14.如果用内燃机驱动,请在起动发动机前保持离合器脱开;泵起动后,检查液体是否进入到泵中,泵是否工作正常,如果长时间无液体进入泵中,应停机检查泵及管路。

NYP高粘度泵相关业绩

1.安徽蜂献蜂业有限公司

输送蜂蜜泵 型号NYP-7-RU-T2-W51高粘度泵,配电机XWD1.1KW-3-23 流量240L/h 压力:1.0Mpa

抽糖浆泵 型号NYP110高粘度泵,配电机XWD11KW-6-9 流量:10m3/h,压力:1.0Mpa

2.集安市益盛永泰蜂业有限责任公司

输送蜂蜜泵NYP110高粘度泵,配电机XWD11KW-6-9 流量:10m3/h,压力:1.0Mpa

3.广水市大别山蜂业有限公司

输送蜂蜜泵 NYP110高粘度泵配,配电机XWD15KW-7-9 流量:10m3/h,压力:0.6Mpa

4.永春县苏坑贵欣源养蜂场

抽蜂蜜泵 NYP110高粘度泵,配电机R87-15KW-226r/min 流量:15m3/h,压力:0.8Mpa

5.浙江江山恒亮蜂产品有限公司

抽蜂蜜泵 型号:NYP110高粘度泵,配电机YCJ112-11KW-226r/min 流量:16m3/h,压力:0.3Mpa

6.城固县天汉农家食品有限公司

抽蜂蜜泵 型号:NYP220高粘度泵,配电机YCJ225-22KW-383r/min 流量:50m3/h,压力:0.6Mpa

输送糖蜜泵NYP110-RU-M1-W51高粘度泵,配电机YCJ225-18.5KW-3 流量:17m3/h,压力:0.8Mpa

7.宣城市宣州区百纯养蜂家庭农场

抽蜂蜜泵 型号:NYP220高粘度泵,配电机XWD18.5KW-7-11 流量:18m3/h,压力:0.8Mpa

8.广州市谭山蜂业有限公司

抽蜂蜜泵 型号: NYP-220B-LU-T1-W12高粘度泵,配电机XWD18.5KW-8-11 流量:20m3/h,压力:1.0Mpa

抽糖蜜泵型号: NYP-220B-RU-T1-W51高粘度泵,配电机YCJ220-11KW 流量:180m3/h,压力:1.0Mpa

9.福建省好邻居食品工业有限公司

抽糖稀泵 型号:NYP220高粘度泵,配电机YCJ225-22KW-383r/min 流量:50m3/h,压力:0.6Mpa

10.常州嘉玛百胜化工有限公司

抽胶水泵 型号: NYP220B-LU-T1-J-W12高粘度泵 配R97-282-22KW(YX3),流量30m3/h,压力1.0Mpa

抽胶黏剂泵型号: NYP220B-LU-T2-J-W11高粘度泵 配XWD18.5KW-8-11,流量20m3/h,压力1.0Mpa

抽胶粘剂泵 型号: NYP220B-RU-T1 -W11高粘度泵 配R97-15KW-206r/min,流量25m3/h,压力1.0Mpa

11.佛山市嘉宏建塑料制品有限公司

抽热熔胶泵 型号: NYP220B-LU-T2 -W11高粘度泵 配XWD15KW-8-11,流量15m3/h,压力0.6Mpa

12.深圳市金斯邦胶粘剂有限公司

输送环氧树脂胶泵 型号: NYP-220B-LU-T1-W12高粘度泵,配电机XWD18.5KW-8-11 流量:20m3/h,压力:1.0Mpa

输送密封胶泵 型号: NYP220B-RU-T1 -W11高粘度泵 配XWD15KW-8-11,流量15m3/h,压力0.6Mpa

输送厌氧胶泵 型号: NYP110-RU-T2 -W11高粘度泵 配XWD15KW-8-11,流量15m3/h,压力0.6Mpa

喷胶泵 型号: NYP220B-RU-T1-W12高粘度泵 配R97-282-22KW(YX3),流量30m3/h,压力1.0Mpa

13.上海把兄弟胶粘剂有限公司

抽环氧树脂胶泵 型号: NYP220B-RU-T1 -W11高粘度泵 配XWD15KW-8-11,流量15m3/h,压力0.6Mpa

抽硅酮密封胶泵NYP220B-LU-T2-J-W11高粘度泵 配XWD18.5KW-8-11,流量20m3/h,压力1.0Mpa

14.上海励致化工有限公司

抽橡胶油泵 型号:NYP50-RU-T2-W11高粘度泵配XWD15KW-8-11,流量6.7m3/h,压力0.6Mpa

抽导轨油泵 型号: NYP220B-LU-T1-J-W12高粘度泵 配R97-282-22KW(YX3),流量30m3/h,压力1.0Mpa

抽汽轮机油泵 型号W4.1ZKR48Z1M1W73双螺杆泵, 配电机1.5KW-2 流量24m3/h 压力:1.0Mpa

15.东莞市胜泰化工有限公司

脱漆剂金属脱漆剂油漆剥离剂

16.深圳市欧斯邦新材料有限公司

抽灌封胶泵NYP220B-LU-T2 -W11高粘度泵 配XWD15KW-8-11,流量15m3/h,压力0.6Mpa

抽硅凝胶泵NYP220高粘度泵,配电机YCJ225-22KW-383r/min 流量:50m3/h,压力:0.6Mpa

17.潍坊天元材料有限公司

沥青输送泵 型号NYP24-RU-T2 -W11高粘度泵 配YCJ100-4KW,流量3m3/h,压力0.6Mpa

抽沥青泵型号NYP24-RU-T2 -W11高粘度泵 配YCJ100-4KW,流量3m3/h,压力0.6Mpa

18.广州禹泰科技有限公司

抽沥青泵 型号NYP320-RU-T2 -W11高粘度泵 配CZR107-37KW,流量50m3/h,压力0.6Mpa

抽沥青泵 型号NYP220B-RU-T1 -W11高粘度泵 配R97-18.5KW,流量30m3/h,压力0.6Mpa

下一篇:张家界水电公司3G80*3C水电站浸没三螺杆泵输