SNH40三螺杆泵性能曲线图电机转速950r/min,介质粘度

SNH40三螺杆泵性能曲线图电机转速950r/min,介质粘度75cst.

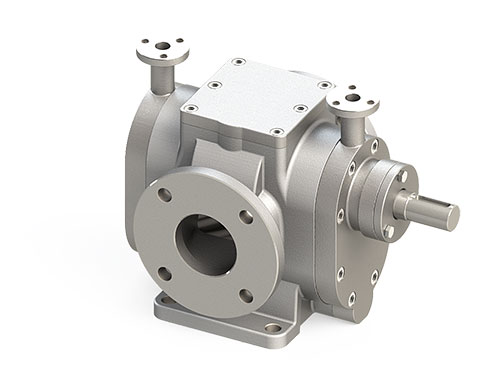

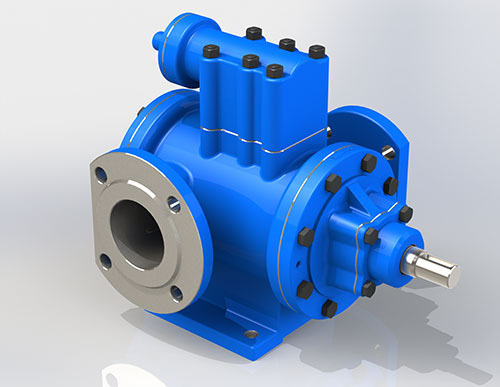

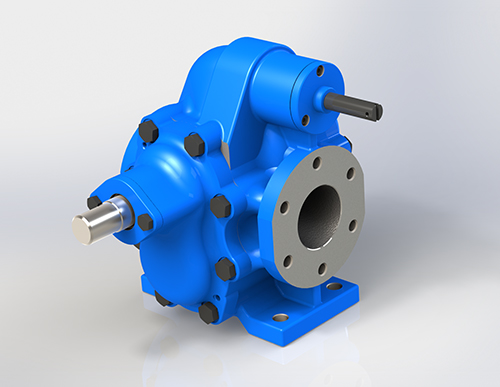

三螺杆泵特点及优点:(1)压力和流量范围宽阔,流量范围0.2~320m3/h 高工作压力可达5MPa;(2)运送液体的种类和粘度范围宽广,粘度范围1mm2/s-760mm2/s;(3)因为三螺杆泵内的回转部件惯性力较低,故可使用很高的转速;(4)吸入性能好,具有的自吸能力;(5)流量均匀连续,振动小,噪音低,几乎没有脉动;(6)三螺杆泵结构坚实,安装方便有(卧式、立式、法兰式、插装式)保养容易;(7)三螺杆泵具有的耐热性,一般工作温度是(1~250°C)超过此温度需 ;(8)根据所输送介质需要还可提供加热或冷却结构;(9)三螺杆泵几乎没有磨损,三螺杆泵只要选型正确,使用寿命长。(10)三螺杆泵的工作。Three screw pump features and advantages: (1) a wide range of pressure and flow, flow range of 0.2 ~ 320 m3 / h top working pressure of 5 mpa;(2) wide range of delivery and type of liquid viscosity, viscosity range 1 was/was/s - 760 s;(3) because the rotary inertia force component inside the three screw pump is low, it can use the high speed;(4) inhalation can good, strong self-priming capacity;(5) flow uniformly continuous, little vibration, low noise, little pulse;(6) three screw pump structure solid, easy installation with (horizontal, vertical, flange, cartridge) easy maintenance.Three screw pump (7) has strong heat resistance, the general working temperature is (1 ~ 250 ° C) beyond the temperature should be specially;(8) according to the needs of the medium can also provide heating or cooling structure;(9) three screw pump almost no wear and tear, three screw pump through proper selection, long service life.High efficiency of three screw pump (10).

注意事项:1.三螺杆泵的转速选用:三螺杆泵的流量与转速成线性关系,相对于低转速的螺杆泵,高转速的螺杆泵虽然能增加了流量和扬程,但功率明显增大,高转速加速了转子与定子间的磨耗,使螺杆泵过早失效,而且高转速螺杆泵的定转子长度很短,极易磨损,因而缩短了螺杆泵的使用寿命。通过减速机或无级调速机构来降低转速,使勘转速保持在每分三百转以下较为合理的范围内,与高速运转的螺杆泵相比,使用寿命能延长几倍。2.螺杆泵的品质:现在市场上的螺杆泵的种类较多,相对而言,的螺杆泵,材质,但价格较高,服务方面有的不到位,配件价格高,订货周期长,可能影响生产的正常运行。国内生产的大都仿制产品,产品质量良莠不齐,在选用国内生产的产品时,在考虑其性价比的时候,选用低转速,长导程,传动量部件材良,额定寿命长的产品。3.杂物不进入泵体:湿污泥中混入的固体杂物会对螺杆泵的橡胶材质定子造成损坏,所以杂物不进入泵的腔体是很重要的,很多污水厂在泵前加装了粉碎机,也有的安装格栅装置或滤网,阻挡杂物进入螺杆泵,对于格栅应及时清捞以免造成堵塞。4.保持恒定的出口压力:螺杆泵是一种容积式回转泵,当出口端受阻以后,压力会逐渐升高,以至于超过预定的压力值.此时电机负荷急剧增加.传动机械相关零件的负载也会超出设计值,严重时会发生电机烧毁,传动零件断裂.为了避免螺杆泵损坏,一般会在三螺杆泵出口处安装旁通溢流阀,用以稳定出口压力,保持泵的正常运转。5.避免断料:三螺杆泵决不允许在断料的情形下运转,一经发生,橡胶定子由于干磨擦,瞬间产生高温而烧坏,所以,粉碎机完好,格栅是螺杆泵正常运转的 条件之一,为此,有些螺杆泵还在泵身上安装了断料停机装置,当发生断料时,由于螺杆泵其有自吸功能的特性,腔体内会产生真空,真空装置会使螺杆泵停止运转。5选型问题:三螺杆泵选型时,要尽可能详尽地了解泵的使用条件,除了运行参数,如流量,压力需要清楚以外,输送介质的特性如介质的腐蚀性,含汽量,含固溶物的比率及固体颗粒的大小,以及介质的工作温度,粘度,比重,对材料的腐蚀性等和泵装置的吸入条件,安装条件均要了解,根据我们的经验,三螺杆泵选型时应注意以下几点:

转速的选择Note: 1. The three screw pump speed selection: a linear relationship with three-screw pump flow rate and rotational speed, low relative to the rotating speed of screw pump, high rotational speed of screw pump, although can increase the flow and head but power obviously increase, high speed accelerate the abrasion between the rotor and stator, must make the premature failure of screw pump, and the high speed of the screw pump stator length is short, easy to wear and tear, thus shortening the service life of the screw pump.Through reducer or stepless speed regulation mechanism to reduce the speed, keep to determine speed at three hundred revolutions per minute (the following reasonable range, compared with the high speed of screw pump, can prolong service life of a few times.2. The quality of the screw pump, now in the market is more, the kinds of screw pump, screw pump imported from rational design, excellent material, but the price is higher, the service aspect some do not reach the designated position, accessories price is high, the order cycle is long, may affect the normal running of production.Domestic production of generic mostly imported products, product quality is good and bad are intermingled, when choosing the products of the domestic, considering its cost-effective, choose low rotation speed, long lead, transmission quantity of parts material is good, rated life long product.3. Ensure that stuff does not enter the pump body: wet sludge mixed with solid debris can cause damage to the rubber stator of screw pump, so make sure debris into the cavity of the pump is not very important, a lot of sewage plant in front of the pump with a grinder, also some installation or mesh grille device, stop the debris into screw pump, the grating should be timely get so as not to cause congestion.4. Maintain a constant outlet pressure: screw pump is a kind of positive displacement rotary pump, when after the outlet is blocked, the pressure will gradually rise, so that more than a predetermined pressure value. The motor load increases sharply. Transmission machinery and related parts load will exceed the design value, serious happens when the motor is burnt, transmission parts fracture. In order to avoid damage of screw pump, typically, bypass the overflow valve is installed on the three screw pump outlet to stable outlet pressure, maintain the normal operation of the pump.5. Avoid cutting: three screw pump must not be allowed in the case of the cutting operation, once happened, the rubber stator due to dry friction, instant high temperature and burn out, so, crushing machine in good condition, grille flow is one of the necessary conditions for normal operation of the screw pump, therefore, some screw pump on pump installation end stop device, when cutting, due to the characteristics of the screw pump has a self-priming function, can produce vacuum chamber, vacuum device can make the screw pump stop running.5 selection problem: three screw pump selection, should understand the using condition of pump as much detail as possible, in addition to the operating parameters, such as flow rate, pressure needs to be clear, the characteristics of medium such as corrosive medium, gas content, including ratio of solid solution and the size of the solid particles, as well as the working temperature, medium viscosity, density, corrosion of materials and pump suction conditions, such as the installation conditions are to understand, according to our experience, three screw pump selection should pay attention to the following:The choice of speed

螺杆磨损五点原因:1、每种塑料,都有一个理想塑化的加工温度范围,应该控制料筒加工温度,使之接近这个温度范围。粒状塑料从料斗进入料筒, 先会到达加料段,在加料段必然会出现干性磨擦,当这些塑料受热不足,熔融不均时,很易造成料筒内壁及螺杆表面磨损增大。同样,在压缩段和均化段,如果塑料的熔融状态紊乱不均,也会造成磨损增快。2、转速应调校得当。由于部分塑料加有剂,如玻璃纤维、矿物质或其他填充料。这些物质对金属材质的磨擦力往往比熔融塑料的大得多。在注塑这些塑料时,如果用高的转速成,则在提高对塑料的剪切力的同时,亦将令相应地产生 多被撕碎的纤维,被撕碎的纤维含有锋利末端,令磨损力大为增加。无机矿物质在金属表面高速滑行时,其刮削作用也不小。所以转速不宜调得太高。3、螺杆在机筒内转动,物料与二者的摩擦,使螺杆与机筒的工作表面逐渐磨损:螺杆直径逐渐缩小,机筒的内孔直径逐渐加大。这样,螺杆与机筒的配合直径间隙,随着二者的逐渐磨损而一点点加大。可是,由于机筒前面机头和分流板的阻力没有改变,这就增加了被挤塑物料前进时的漏流量,即物料从直径间隙处向进料方向流动量增加。结果使塑胶机械生产量下降。这种现象又使物料在机筒内停留时间增加,造成物料分解。如果是聚乙烯,分解产生的氯化氢气体加强了对螺杆和机筒的腐蚀。4、 物料中如有碳酸钙和玻璃纤维等填充料,能加快螺杆和机筒的磨损。5、 由于物料没有塑化均匀,或是有金属异物混入料中,使螺杆转动扭矩力突然增加,这种扭矩超出螺杆的强度 ,使螺杆扭断。这是一种非常规事故损坏。Screw wear five reasons: 1, each type of plastic, there is a ideal plasticizing processing temperature range, temperature should be controlled cylinder processing, make it close to the temperature range.Granular plastic from the hopper into the cylinder, will first reach the feeding section, the charging period of inevitable dry friction, when the plastic is heated, fused inequality, very easy to cause the inner wall of the cylinder and the screw surface wear.Similarly, in compression and homogenization, if uneven plastic molten state of disorder, can cause wear faster.2, rotational speed should be proper calibration.As part of the plastic with enhancer, such as glass fiber, minerals, or other filling material.The material of metal friction often is much bigger than the molten plastic.When these plastic injection molding, if with high speed, is in the increase of plastic shear force at the same time, will also strengthen accordingly produce more fiber is torn, torn fiber containing sharp end, the wear and tear strength increased greatly.Inorganic minerals in the metal surface high-speed taxi, scraping effect is also not small.So the speed shoulds not be too high.3, screw rotation inside the barrel, friction material with both the screw and barrel of the surface of the work gradually wear: screw diameter reduced gradually, the barrel inner hole diameter increase gradually.In this way, the matching of the screw and barrel diameter clearance, with the gradual wear and tear of the a little bit more., however, because of the barrel in front of the nose and shunt plate resistance has not changed, which adds to the forward extrusion material leakage flow, the material feeding direction from diameter clearance flow has increased.Results decreased plastic machinery production.This phenomenon and make the material stay in the barrel time increased, the material break down.If it is polyethylene, decomposition of hydrogen chloride gas is used to strengthen the corrosion of the screw and barrel.4, material such as calcium carbonate and the filling material such as glass fiber, can speed up the screw and barrel of the wear and tear.5, as there is no uniform plasticizing, material or metal foreign bodies with material, to rotate the screw torque force suddenly increases, the torque beyond the ultimate strength of the screw, the screw twist off.This is a kind of unconventional accident damage.