输送丁苯乳胶泊东泵业推荐使用双螺杆泵或者高

丁苯胶乳是以丁二烯和苯乙烯经低温聚合而成的稳定乳液。

根据苯乙烯含量、乳化剂和聚合温度等的不同,而有多种品种,其性能和用途也不同。R丁苯胶乳沥青改性剂是根据改性沥青、改性乳化沥青的特性专门研制的。在公路工程中,广泛用于制备各种喷洒型、拌合型用的改性乳化沥青,以及高等级路面,桥面等道路工程的微表处、稀浆封层、粘层油的沥青改性和屋面、地下洞库等工程材料的改性。

丁苯胶乳与阳离子沥青乳化剂直接调和,通过简单搅拌即可制成改性乳化沥青。用量一般为2%-4%(干基),粘层油一般取下限,微表处取上限,用改性乳化沥青一般为10%-20%(干基)。R丁苯胶乳沥青改性剂是根据改性沥青、改性乳化沥青的特性专门研制的。在公路工程中,广泛用于制备各种喷洒型、拌合型用的改性乳化沥青,以及高等级路面,桥面等道路工程的微表处、稀浆封层、粘层油的沥青改性和屋面、地下洞库等工程材料的改性。

输送丁苯乳胶泵根据不同工况情况,我公司推荐给客户不同的泵形式,在粘度较高的情况使用NYP高粘度泵,可以配用减速机.在粘度不是很大的时候使用双螺杆泵,泵的流量,但是这两种泵都属于切削传输,如果怕影响分子链的结构,我们会给客户使用单螺杆泵.下面我介绍一下高粘度泵和双螺杆泵的性能.为大家做参考.

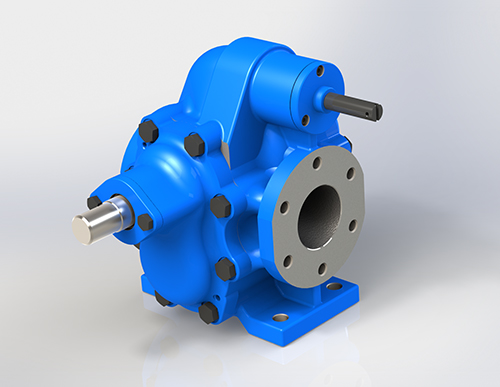

高粘度泵:

●高粘度齿轮泵并不能产生压力,它只是输出流量。压力低或无压力,说明高粘度齿轮泵没有吸入液体或泄漏严重。High viscosity gear pump does not generate pressure, it is only the output flow.Pressure is low or no pressure, high viscosity gear wheel pump don't inhale the liquid or leakage is serious.

电动机输出功率偏小、齿 轮泵排量选得过大或压力调得过高时,也会造成压力不足 当然,压力表损坏或压力表节流孔堵塞时也显示不出压力,此时可换装一个新的压力表检查。Small motor output power, gear wheel pump capacity to choose too large or pressure too high, can cause stress Pressure gauge damage or pressure gauge orifice jams, of course, also could not show pressure, can change a new pressure gauge to check at this time.

如果确认泵无流量输出,可能是由于泵安装有误、泵的转向不对,或吸人侧(进液口及吸液管道)堵塞、出口止回阀装反或卡死了,也有可能是驱动轴断裂了。If confirmed that no flow pump output, could be turned to the pumps due to pump installation is wrong, wrong, or suction side (liquid into the mouth and suck liquid pipeline jam, export check valve installed backwards, or card is dead, it is possible that the drive shaft fracture.

高粘度泵在转速过低时会引起出液量不足,这种现象往往是由于泵的驱动装置打滑或功率不足所致。此时应检查齿 轮泵的实际转速、泵与电动机的联接及功率匹配情况等。High viscosity pump in low speed can cause insufficient quantity of produced liquid, this phenomenon is often due to the slippage of the pump drive or insufficient power.Check the gear wheel pump at this time of the actual speed, pump and motor connection and power matching, etc.

●高粘度泵在开始运转前,往齿轮泵的壳体内灌满待输送的液体,便于 启动。若环境温度低于冰点,应预先向泵内通入热蒸汽,进行预热处理,然后才可启动齿轮泵。高粘度泵的旋转方向要与进、出油口相符。齿轮泵若是 次运行,或长期闲置后再使用, 好在空载或小负荷情况下先跑合一小时左右。如果在跑合阶段预先觉察出异常温升、泄漏、振动和噪声时,应停机检查。高粘度齿轮泵的支座或法兰与其驱动电机应采用共同的安装基础,基础、法兰或支座均需具有足够的刚度,以减小齿轮泵运转时产生的振动和噪声。电动机与齿轮泵须用弹性联轴器连接,同轴度小于0.1毫米,倾斜角不得大于1度。安装联轴器时不得用锤敲打,以免伤害齿轮泵的齿轮等零件。若用带轮、链轮等驱动时应设托架支承,以防主动齿轮轴承受径向力。紧固齿轮泵、电动机的地脚螺钉时,螺钉受力应均匀,连接。用手转动联轴器时,应感觉到齿轮泵能够轻松地转动,没有卡紧等异常现象出现,然后才可以配管。High viscosity pump before starting work, to gear pump casing filled with liquid, facilitate safe launch.If the environment temperature is below freezing, should advance to pump into the hot steam, preheating treatment, and then to start the pump.The direction of rotation of the pump with high viscosity, oil outlet in accord.Gear pump is the first run, or long-term idle before using, had better under the condition of no load or small load to run one hour or so.If in the running-in stage in advance detect abnormal temperature rise, leakage, vibration and noise, should stop check.High viscosity gear pump bearing or flange should adopt a common drive motor installationFoundation, foundation, flange or support all needs to have enough rigidity, to reduce the vibration of gear pump is running and noise.Motor and gear pump with elastic shaft coupling, coaxial degree is less than 0.1 mm, Angle shall not be greater than 1 degree.When installing coupling hammer shall not be used, in order to avoid damage of the gear pump gearAnd other parts.If use the belt wheel, wheel, etc, shall set bracket support, in case of driving gear bearing by the radial force.Ground screw fastening gear pump, motor, screw force should be uniform, reliable connection.Turn the coupling with the hand, should feel can easily turn the gear pump, no abnormal phenomenon such as clamping, then can be piping.

高粘度齿轮泵的吸油管道内径应足够大,并避免狭窄通道或急剧拐弯、减少弯头,去除不 的阀门、附件,尽可能地降低泵的安装高度,缩短吸油管道的长度,以减少压力损失。管接头等元件的密封要良好,以防止空气侵入,从而控制气穴与气蚀的发生。止回阀与 阀在齿轮泵的输出管路上 好安装一个止回阀。这样在检修泵及输出管道时,系统中的液体不会发生倒流。齿轮泵带负荷停车时,亦可防止泵倒转而在其输出管道内产生局部真空。应当注意,出口止回阀不能装反或出现卡死现象。高粘度泵的出口管路上还应当设置 阀等保护装置,这样一旦泵的出口通道发生堵塞,就可以打开 阀卸压。 阀可以与泵体或泵盖铸成一体,也可以单独装配。对于需要正反转的高粘度齿轮泵,其进出口管路上均需设置 阀。High viscosity gear pump oil suction pipe diameter should be large enough, and to avoid the narrow channel, or a sharp turn, reducing elbow, remove unnecessary valves, fittings, as much as possible to reduce the installation height of pump, shorten the length of the oil suction pipe, in order to reduce the pressure loss.Components, such as pipe joint sealed well, in order to prevent the air intrusion, thus control air-pocket and the occurrence of cavitation.Check valve and relief valve on the output of the gear pump tube had better install a check valve.In the overhaul pump and output pipe, the system of fluid backflow will not occur.Gear pump to stop loading machine, can be in the output pipe to prevent pump reverse, and create a partial vacuum.It should be noted that the outlet check valve cannot be installed backwards or stuck.High viscosity of the pump outlet pipe also shall set up relief valve or other protective device on the road, so that once the clogging pump export channels, can open the relief valve pressure relief.The relief valve can be cast and pump body and pump cover, also can separate assembly.For high viscosity gear pump need positive &negative, import and export all needs to set up the line safety valve.

高粘度泵是输送高粘度液体的齿轮泵,应做到在较低的功耗、较少的泄漏、较大的压力下输出 多的流量。在确定所要输送的介质时,应该严格遵循产品说明书上的规定,尽量使用厂家推荐的流体介质,并注意考虑系统的工作温度范围。当希望在某一较宽的温度范围内使用时,输送介质的粘度指数应该高些。输送介质不仅是能量传递的中介,而且也是润滑、密封及传热介质。液体粘度过高会增加内摩擦阻力,降低输出功率,浪费能量,并产生过高的系统温度.高粘度齿轮泵的出口管路上应当设置 阀等保护装置,这样一旦泵的出口通道发生堵塞,就可以打开 阀卸压。对于需要正反转的高粘度齿轮泵,其进出口管路上均需设置 阀。High viscosity pump is conveying liquid with high viscosity gear pump, should be in lower power consumption, less leakage, under the pressure of large output the most traffic.When determining to conveying medium, we should strictly follow the provisions of the product manuals on use manufacturers recommend fluid as far as possible, and pay attention to consider the system operating temperature range.When you want to use in a wide temperature range, medium viscosity index should be higher.Medium is not only the energy transfer intermediary, but also lubrication, sealing and heat transfer medium.Liquid viscosity is too high will increase internal friction resistance, lower output power, waste of energy, and generate high temperature system. High viscosity gear pump outlet pipe shall set up relief valve or other protective device on the road, so once the clogging pump export channels, can open the relief valve pressure relief.For high viscosity gear pump need positive &negative, import and export all needs to set up the line safety valve.

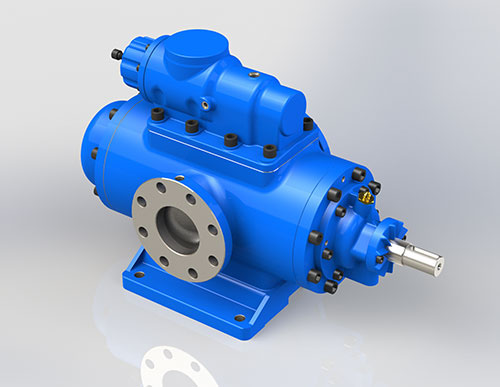

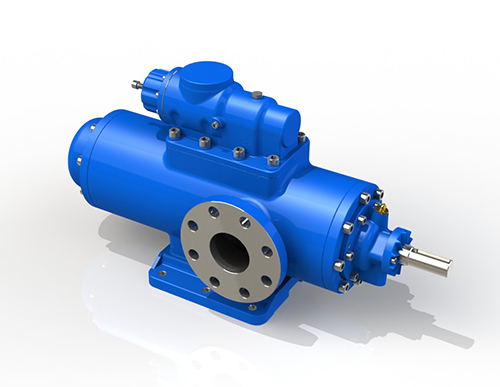

双螺杆泵:

●性能范围:Range of performance:

1、 高工作压力4.0MPa 1, the maximum working pressure of 4.0 MPa

2、流量范围 1~1000m3/h 2, 1 ~ 1000 m3 / h flow range

3、温度范围-20~120℃ 3-20 ~ 120 ℃, temperature range

4、介质粘度 1~3000mm2/s,降低转速可达到106mm2/s 介质粘度对双螺杆泵性能影响较大,泵的名义排量是指在特定粘度条件下的排量,为泵能在较 下工作,在试验不充分时,建议按下列粘度条件选择转速:介质粘度cSt转速r/min <4001500 400 ~12001000 1200~3600750。

4, 1 ~ 3000 was/s, medium viscosity reducing speed can reach 106 was/s medium viscosity influence the performance of double screw pump, pump displacement refers to the specific viscosity of conditions in the name of the displacement, in order to ensure the pump can work in high efficiency, when the test is not sufficient, suggestion choice speed on the viscosity of the following terms and conditions: medium viscosity cSt speed r/min < 4001500 400 ~ 12001000, 1200 ~ 400.

●双螺杆泵有密封式和不密封式两种类型,按介质从一端还是从两端进入啮合空间,双螺杆又被分为双吸式和单吸式两种结构。双螺杆泵是外啮合的螺杆泵,它利用相互啮合,互不接触的两根螺杆来抽送液体。双螺杆泵为一种双吸式非密闭的双螺杆泵。一端伸出泵外的主动螺杆由原动机驱动。主动螺杆与从动螺杆具有不同旋向的螺纹。螺杆与泵体紧密贴合。从动螺杆是通过同步齿轮由主动螺杆带动的。Double screw pump has sealed and not enclosed two types, according to the medium from the side or from both ends into space meshing, double screw was divided into double suction type and structure of single suction type two kinds.Screw pump, twin screw pump is the external gear utilizing the mesh each other, mutual contact of two screw to pumping liquid.Double screw pump is a kind of double suction not airtight double screw pump.Active outside the side out of the pump screw driven by a prime mover.Driving screw and driven screw thread with different handedness.Screw pump body and tightly.Driven screw is driven by synchronous gear by the active screw.

●双螺杆泵作为一种容积式泵,泵内吸入室应与排出室严密地隔开。因此,泵体与螺杆外圆表面及螺杆与螺杆间隙应尽可能小些。同时螺杆与泵体、螺杆与螺杆间又相互形成密封腔,密闭,否则就可能有液体从间隙中倒流回去。Double screw pump as a positive displacement pump, the pump suction chamber should be closely separated and discharge chamber inside.Therefore, the pump body and screw cylindrical surface and screw and screw clearance should be as small as possible.Screw pump body and at the same time, each other between the screw and screw and form a sealed chamber, ensure airtight, otherwise there may be liquid backflow from the gap.

●双螺杆泵可分为内置轴承和外置轴承两种形式。在内置轴承的结构型式中轴承由输送物进行润滑。外置轴承结构的双螺杆泵工作腔同轴承是分开的。由于这种泵的结构和螺杆间存在的侧间隙,它可以输送非润滑性介质。此外,调整同步齿轮使得螺杆不接触,同时将输出扭矩的一半传给从动螺杆。正如所有螺杆泵一样,外置轴承式双螺杆泵也有自吸能力,而且多数泵输送元件本身都是双吸对称布置,可轴向力,也有很大的吸高。Double screw pump can be divided into internal bearing and the outer bearing two forms.In the built-in bearing structure bearing lubrication by conveying material.Working with external bearing structure of the double screw pump bearings are separated.Owing to the pump structure and side clearance between screw, it can transport non-lubricative medium.In addition, the adjustment of the synchronous gear makes the screw does not contact, at the same time the output torque of the half to driven screw.Like all of the screw pump, external bearing type twin-screw pump, and most are double suction pump element itself symmetric arrangement, can eliminate the axial force, also has a lot of high absorption.

●双螺杆泵系列产品分为单吸双螺杆泵和双吸双螺杆泵两大类。该系列产品具有的螺杆型线和与之配套的结构,广泛适用于石油、化工、冶金、钢铁、电力、船舶、制药、食品、建材等各种行业,其适用介质之多、输送范围之广、应用工况之复杂是其它泵类产品无法比拟的。这些特点也使得该系列泵具有潜在的使用发展前景。Double screw pump series products are divided into single suction of two kinds of double screw pump and double suction double screw pump.This series of products have special screw lines and form a complete set with the special structure, widely used in petroleum, chemical industry, metallurgy, steel, electricity, shipbuilding, pharmaceutical, food, building materials and other industries, by as much as its applicable medium, transmission range wide, application condition of the complex is unmatched by other pump product.These features also makes the use of this series of pumps with potential development prospects.

●泵体内装有两根左、有施单头螺纹的螺杆,主动螺杆2由动力机驱动转动时,靠同步齿轮1带动从动螺杆3转动。两根螺杆以及螺杆与泵体. 之间存在着间隙,该间隙靠齿轮和轴承。其间隙大小,取决于液体粘度、工作压力等因素。由于每根螺杆两端螺纹的旋向相反,螺杆转动时,由螺杆啮合线形成的泵工作腔。Equipped with two left in the pump body, a single thread screw, active screw driven by engine 2 turns, driven by synchronous gear 1 driven screw 3 rotation.Two screw and screw and pump body. There is a gap between the gap by gear and bearing.The gap size, depends on the liquid viscosity, pressure and other factors.Because each thread rotate to the opposite on both ends of the screw, the screw rotates, formed by the screw meshing line pump working chamber.

输送橄榄油泵 SNH440R52U12.1W21三螺杆泵 石家庄新宇三阳实业有限公司

输送柴油泵 SMH80R42E6.7W23三螺杆泵 山东祥通橡塑集团有限公司

燃料油装船泵 SNH940R46E6.7Y-W29三螺杆泵 天津科迈化工有限公司

输送丁苯乳胶泵 W2.1ZK34M1W73双螺杆泵 江苏雅克科技股份有限公司

输送原油泵 SNGF80R46G10W21三螺杆泵泵 青岛新宇田化工有限公司

输送染料泵 G135-1单螺杆泵 江西昌昱实业有限公司

粘胶剂输送泵 NYP110-RU-T2-W51高粘度泵 浙江轻机实业有限公司

输送原油泵 SNH120R46U12.1W2三螺杆泵 江苏赛欧信越消泡剂有限公司

原油输送泵 SNH210R42E6.7W2三螺杆泵 南京聚隆科技股份有限公司

可可油输送泵 KCB18.3齿轮泵 云南江城泰裕钾肥有限公司

锅炉燃烧器供油泵 SNH210R46E6.7W1三螺杆泵 河南天宇肥业有限公司

橄榄油输送泵 SNH210R46E6.7W1三螺杆泵 河北新世纪周天生物科技有限公司

输送液压油泵 KCB33.3齿轮泵 山西焦化集团有限公司

枣汁输送泵 SNH280R46E6.7W2三螺杆泵 山东石大科技有限公司

输送粘合剂泵 NYP110-RU-T1-J-W51高粘度泵 山西天脊煤化工集团股份有限公司

输送柴油降凝剂泵 G25-2单螺杆泵 山西阳煤丰喜肥业(集团)有限责任公司

润滑脂输送泵 SMH80R36E6.7W23三螺杆泵 亿利资源集团有限公司

输送碱性胶水泵 NYP220B-RU-T1-J-W11高粘度泵 天津大沽化工股份有限公司

沥青喷射泵 NYP-220高粘度泵 广西柳州化工控股有限公司

基础油输送泵 SNH1700R46U12.1W2三螺杆泵 济南圣泉集团股份有限公司

输送糖蜜泵 NYP110-RU-T1-W11高粘度泵 建滔(河北)化工有限公司

输送润滑油泵 SNH1300R42U12.1W21三螺杆泵 宜宾天原集团股份有限公司

输送丁苯乳胶泵 NYP110-RU-T1-W11高粘度泵 山东海龙股份有限公司

污泥输送泵 G40-1V-W111单螺杆泵减速 山东潍焦集团有限公司

输送丁苯乳胶泵 NYP110-RU-T1-W11高粘度泵 河南天冠企业集团有限公司